Blog Posts

High-Security Solutions For Military And Defense Welding

Welding in military and defense applications demands precision and strength and an unparalleled level of security and safety. The integrity of the welds must be impeccable, as they often contribute to the safety and functionality of critical infrastructure and equipment. This necessitates specialized solutions, such as pressurized welding enclosures, that address the unique challenges of these settings, particularly in terms of safety, efficiency, and compliance with stringent regulations.

The Importance of Safety in Military Welding Operations

Safety is paramount in military and defense welding, given the potentially hazardous environments in which these operations occur. Maintaining a secure environment is essential, whether on a battlefield, in a shipyard, or within a defense manufacturing facility. Pressurized environments play a significant role in ensuring that the welding process is contained and that personnel are protected from harmful fumes, sparks, and other hazards.

Pressurized Welding Enclosures: A Critical Component

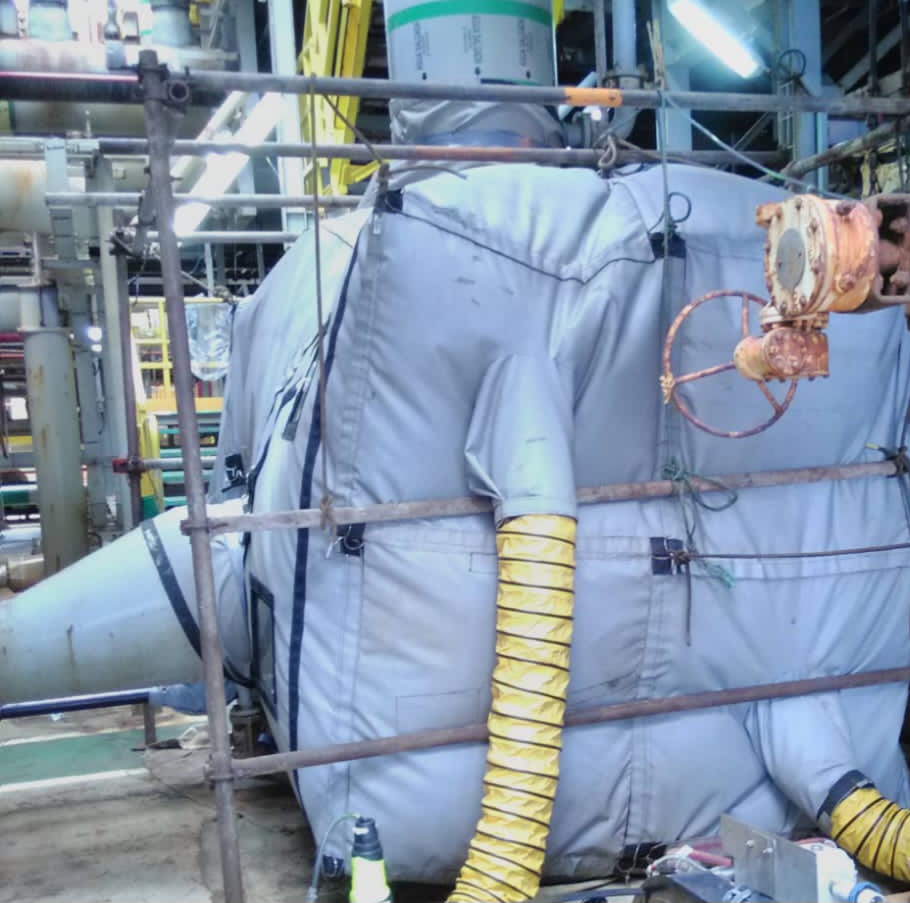

Pressurized welding enclosures withstand the stringent requirements of military and defense settings. These enclosures provide a controlled environment where welding can be performed safely, even in locations with volatile or sensitive conditions. By maintaining a positive pressure inside the enclosure, these systems prevent the ingress of contaminants that could compromise the quality of the weld or pose a safety risk. The ability to control the atmosphere within the enclosure is particularly vital when welding in environments that are exposed to dust, chemicals, or other airborne particles.

For example, in submarine construction, where even the smallest defect can have catastrophic consequences, safety habitats ensure that the welding process remains uncontaminated by the surrounding environment. This not only enhances the quality of the welds but also increases the overall safety of the operation.

Advanced Safety Measures with Pressurized Safety Enclosures

Another crucial measure in military and defense welding is the use of pressurized safety enclosures. These enclosures go beyond the basic containment of the welding process to offer advanced safety features tailored to the needs of high-stakes environments. They provide an added layer of protection by incorporating fire-resistant materials, secure locking mechanisms, and robust ventilation systems that prevent the buildup of hazardous gases.

In defense manufacturing, where precision and safety are non-negotiable, confined safety habitats are indispensable. They ensure that welding activities can be carried out without risk to personnel or the surrounding infrastructure. The ability to quickly set up and dismantle these enclosures also makes them ideal for mobile or temporary installations, such as forward operating bases or emergency repair stations.

Enhancing Efficiency and Safety with PetroHab Solutions

As safety concerns in military welding continue to evolve, so do the solutions designed to address them. At PetroHab, we provide the Petro-Lite Hot Work Safety Enclosure (HWSE), a pioneering product in safe welding practices. Its Quadra-Lock panel interlocking technology (PIT) ensures that panels can be swiftly and securely assembled, offering an efficient setup that can be adapted to various operational needs, whether on scaffolding or standalone frames. The premium silicone-coated fiberglass fabric used in these panels is ANSI/FM 4950 certified, ensuring the enclosure meets the highest safety standards.

These panels can be connected and ready for use in just five minutes, requiring no more than two personnel. This efficiency is particularly beneficial in military settings, where time and human resources are often limited. The enclosure can be affixed to standard scaffolding or a custom-made frame, providing flexibility in various operational scenarios.

Conclusion

High-security solutions like pressurized welding enclosures are essential for the success and safety of military and defense operations. Companies like PetroHab are at the forefront of providing these advanced solutions, helping safeguard the personnel and infrastructure critical to national security. As the demands of military welding continue to grow, so will the need for innovative and adequate safety measures to meet these challenges head-on.